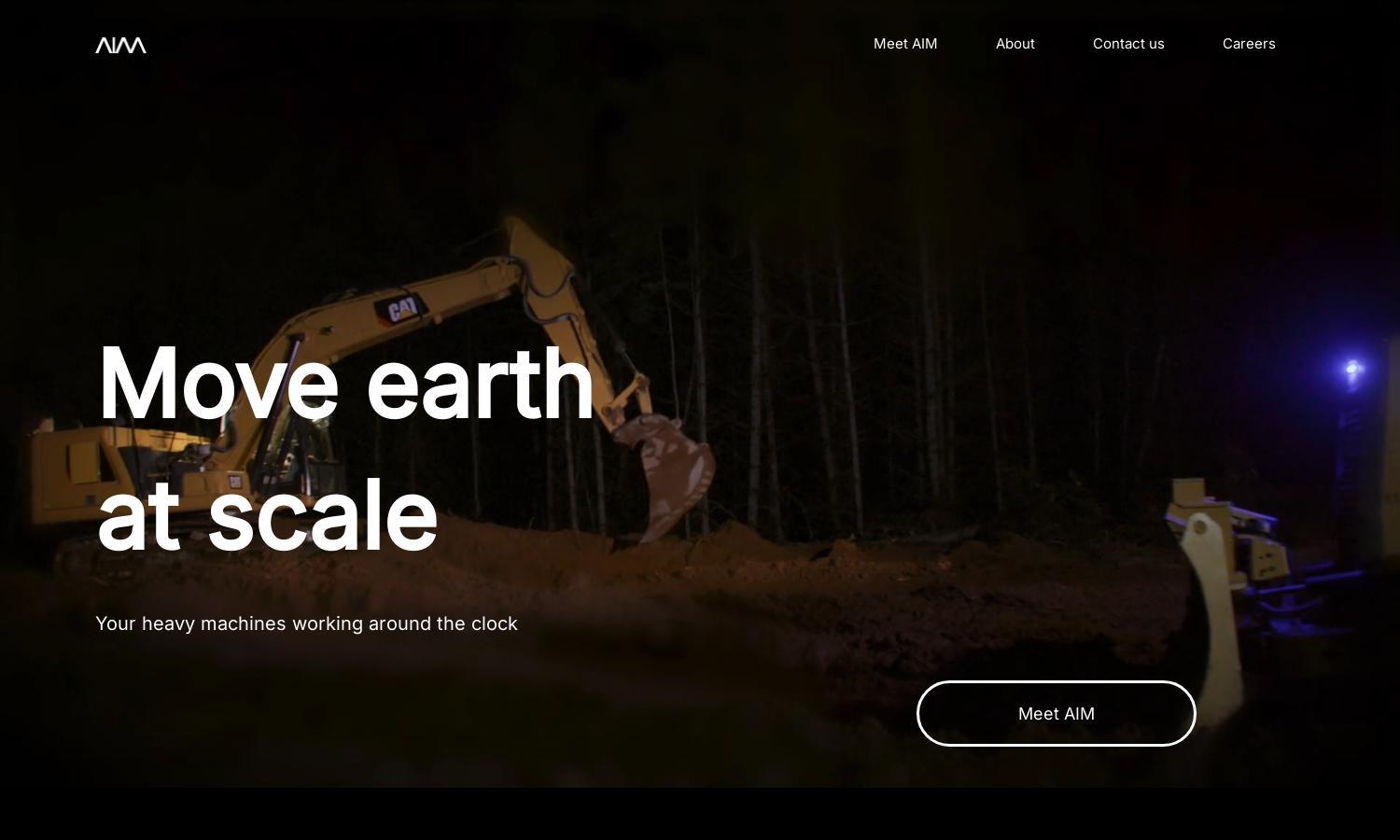

AIM Intelligent Machines

About AIM Intelligent Machines

AIM Intelligent Machines revolutionizes construction by retrofitting heavy equipment for autonomous operation. Targeting industries such as mining and construction, AIM enhances safety and productivity by eliminating operator presence, ensuring 360-degree safety, and allowing equipment to run continuously, thereby maximizing utilization and ensuring a zero-accident track record.

AIM Intelligent Machines offers flexible pricing plans to suit various project scales. Users can choose from tiered subscriptions that provide access to innovative retrofitting solutions. Upgrading enhances safety features, operational efficiency, and overall productivity, making AIM a valuable investment for companies focused on scalable and safe automation.

AIM Intelligent Machines features an intuitive layout that simplifies user navigation. The seamless design enhances user experience, allowing easy access to automation tools and resources. Users can effortlessly interact with advanced safety features and retrofitting options, making AIM’s interface both functional and user-friendly for all levels of expertise.

How AIM Intelligent Machines works

Users begin by booking a consultation with AIM Intelligent Machines to discuss their existing heavy machinery. Following onboarding, the AIM system is retrofitted to enable autonomous operation. Users can then navigate a user-friendly interface, monitoring and managing equipment remotely while benefiting from improved safety and productivity in construction projects.

Key Features for AIM Intelligent Machines

Fully Autonomous Heavy Machinery

AIM Intelligent Machines uniquely retrofits existing construction equipment, transforming them into fully autonomous machines. This feature empowers industries to enhance safety, operate continuously, and utilize machinery like never before, significantly reducing the need for manual labor while ensuring optimal operational efficiency.

360-Degree Safety Mechanisms

AIM Intelligent Machines integrates advanced 360-degree safety mechanisms into retrofitted equipment, ensuring a zero-accident operational record. This key feature protects workers and significantly reduces hazards, allowing automated equipment to operate confidently in challenging environments while maintaining the highest safety standards in the industry.

Upskilling Opportunities for Employees

With AIM Intelligent Machines, automation frees up valuable resources for employees to focus on advanced site planning and analytics tasks. This unique feature not only boosts efficiency but also provides upskilling opportunities, empowering the workforce to transition into higher-value roles and adapt to growing industry demands.